基于物联网、大数据、云计算等核心技术能力,利用各类传感器采集企业关键用电和设备运行数据,从企业安全、节能出发,深度采集变配电房全线路用电数据,并提供运行状态监测、故障报警、异常预警等服务,实现配电室“无人值守、少人值班”。建设企业用电设备全生命周期管理,提供一物一码的管理方式,全方位的掌控设备的健康指数,建立资产详细档案、维护记录、维修记录、生命周期、运行状态及数据等管理。智能运维中心,与在线监测和电力设备管理深度融合,对运维工作进行全过程的管理。

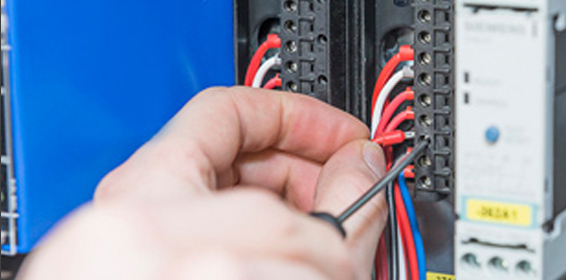

配电房多分线、分路数据用电在线实时监测。

用电安全,漏电监测。

视频监测、环境温湿度、水浸监测、门禁、消防安全。

电能质量监测、电力设备安全、能耗数据分析、用能趋势分析、电能质量管理、设备用能分析、月度专业分析报告。

通过小程序、APP扫码的模式管理电气设备,并全程管理电气设备全生命周期,记录所有运维日志。

当系统诊断出异常时,精确定位,及时以界面消息,短信、APP推送等方式通知用户和运维人员。

与在线监测和资电力设备管理深度融合,对运维工作进行全过程的管理。

所有用电数据云上存储,更安全。

提供电气设备一物一码管理,并记录设备的所有运维日志。

大数据分析、诊断用户安全用电健康指数。

高并发主动上报、多维感知测量、多种通讯方式。

24小时线下运维团队,为你的安全用电保驾护航。

工业园区、科技园区

商场、酒店、公寓

写字楼

工业企业

医院、学校等领域

在线解答,为您解决问题

配电站运维平台

基于物联网、大数据、云计算等核心技术能力